From Fiber to Pixel: The Full-Link Digital Revolution of the Global Fashion Industry

In traditional perception, the journey of a garment—from a designer’s sketch to a prized item in a consumer’s wardrobe—comes to an end with the delivery of the physical product. Today, however, cutting-edge fashion technology enterprises are completely rewriting this industry mindset: the lifecycle of a garment does not terminate with its delivery in the physical world; instead, it embarks on a brand-new chapter in the digital universe.

I. The Digital Rebirth of Fiber: Infusing Data into Fabrics

Leading supply chain innovators are vigorously advancing the Digital Fiber Initiative, endowing each batch of fabric with a unique digital identity. Leveraging Internet of Things (IoT) technology and blockchain authentication, every transfer, processing step, and even design modification of the fabric—from textile factories in Asia to retail terminals in Europe and America—is accurately recorded on an immutable digital thread.

This in-depth digitalization has driven transformative industry changes:

- Transparent supply chains as a competitive barrier: Brands no longer rely on verbal claims to gain market trust. Partners can real-time verify the raw material traceability, carbon footprint data, and craft heritage of each garment, achieving full-dimensional transparency of supply chain information.

- Global collaborative design as an industry norm: Designers can collaborate synchronously on the same “digital fabric” across time zones, shortening the development cycle of virtual samples by over 60% and significantly improving design efficiency.

- Precise matching of market supply and demand: Real-time access data from digital fabric libraries serves as a core indicator for predicting global fashion trends, helping brands pre-position and avoid risks of overstock or slow-moving styles.

Case Study: Global sportswear giant Nike has piloted fabric digitalization. It has equipped fabrics for some high-end sports lines with blockchain traceability tags. Consumers can scan the tags to view the entire process of the fabric—from recycled polyester fiber and spinning/weaving to garment manufacturing—and also access the fabric’s carbon emission data. This initiative not only strengthens the brand’s sustainable development image but also turns supply chain transparency into a core competitive advantage of its products.

II. Intelligent Reflection of Production Systems: From Linear Processes to Digital Networks

The pyramid hierarchical structure of the traditional fashion industry is being completely reconstructed by the digital wave. Forward-thinking manufacturing enterprises are no longer focusing solely on improving production efficiency; instead, they are striving to build intelligent production systems that can respond to market signals in real time:

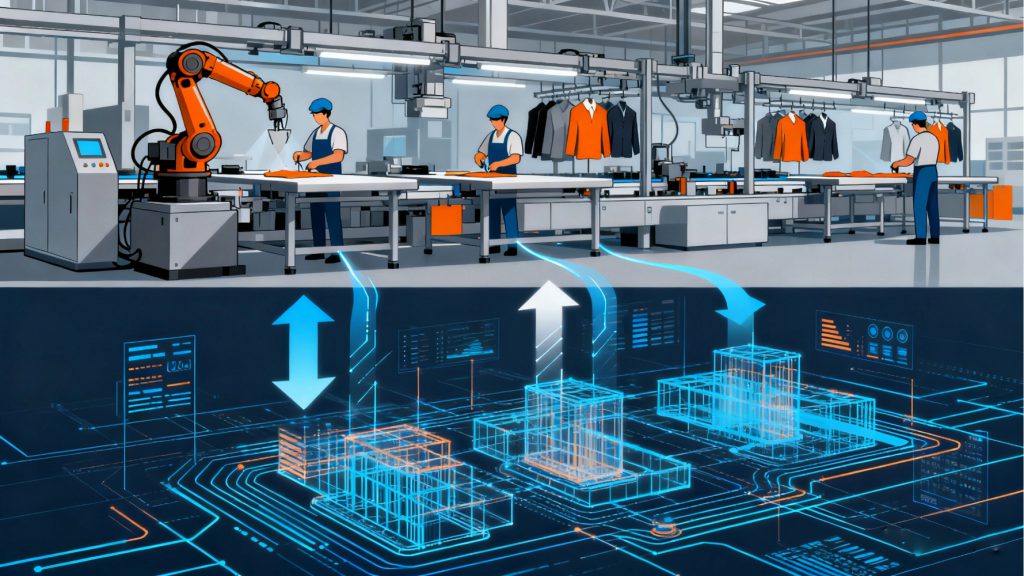

- Implementation of digital twin factories: Every link of the physical production line is precisely mirrored in the digital space. Core data such as process parameters, capacity allocation, and quality control standards can be updated in real time, enabling enterprises to monitor and adjust production status at any time.

- Demand-driven flexible production taking shape: Virtual fitting data and market feedback during the pre-sale phase are directly integrated into the production scheduling system, helping enterprises achieve truly small-batch, fast-response production and reduce waste of ineffective capacity.

- Comprehensive closure of quality traceability loops: Each finished product is attached with an exclusive digital identifier. Consumers only need to scan the code to fully understand the full-link journey of the garment from fiber to finished product, realizing traceable and verifiable product quality.

Typical case data shows that enterprises completing full-link digital transformation can shorten the new product launch cycle by 40%, increase inventory turnover rate by 65%, and achieve significant improvements in sustainability through on-demand production models.

Case Study: Shenzhou International, a leading domestic garment manufacturer, has built a digital twin production system, replicating the production line of its Ningbo factory 1:1 on a digital platform. By real-time collecting data such as equipment operation, worker operation processes, and fabric waste, the enterprise can predict production bottlenecks in advance. It can also simulate capacity allocation plans in the digital twin system based on changes in brand orders and synchronize them to the physical production line. This model has shortened its order delivery cycle by 35% and increased fabric utilization rate by 8%.

III. Dimensional Expansion of Consumer Experience: Breaking the Interactive Boundaries of Fitting Rooms

Virtual fitting technology is only the starting point of consumer experience digitalization. The real cutting-edge exploration of the industry lies in building an integrated “physical-digital” continuous experience field:

- Popularization of personalized digital wardrobes: Each physical garment purchased by users comes with a customizable digital version. These digital garments can be used for dressing in virtual socializing and gaming scenarios, expanding the usage scenarios and value of clothing.

- Upgrade of interactive product storytelling: With AR technology, unique patterns and exquisite craft details on garments can “speak for themselves,” telling consumers the behind-the-scenes design stories and cultural origins, and endowing products with deeper emotional value.

- Formation of social dressing ecology: Users can mix and match digital clothing from different brands in virtual spaces to create exclusive dressing styles. These virtual outfits not only serve as sharing materials on social platforms but also gradually evolve into a new type of social currency and a way of self-expression.

Relevant research data indicates that brands providing immersive digital experiences have a customer retention rate 2.3 times higher than the industry average, and the average daily duration of users participating in brand-related activities has also increased by 4 times.

IV. Reconstruction of Industrial Infrastructure: From Tool Supply to Ecosystem Building

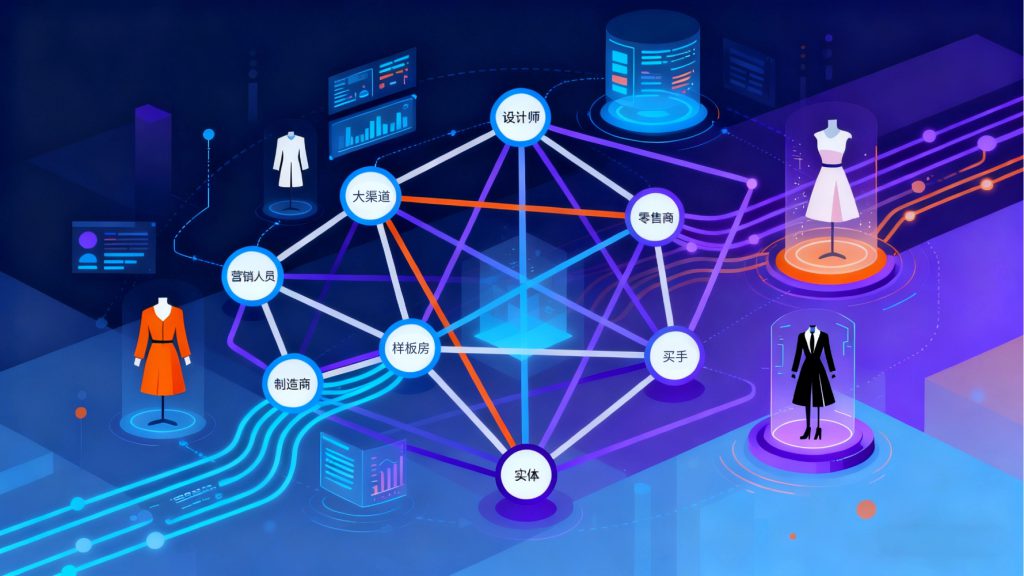

The true industry transformers are shifting from being mere product manufacturers to providers of industrial digital infrastructure. What they are building is by no means a single software tool but a complete ecosystem covering three key levels:

- Infrastructure Layer: Digital Materials Science

- Continuously advancing the digital modeling of the precise physical properties of fabrics;

- Building a cloud-based material library supporting real-time rendering and physical property simulation;

- Formulating cross-brand universal digital fabric standards and protocols to achieve industry-wide data interoperability.

- Application Layer: Intelligent Collaboration Platforms

- Developing design collaboration systems supporting globally distributed teams to break geographical communication barriers;

- Building a data middle platform connecting consumer insights with production decisions to realize precise matching of demand and supply;

- Creating integrated experience solutions combining virtual exhibition halls and physical retail to bridge online and offline consumption scenarios.

- Ecosystem Layer: Value Exchange Network

- Establishing copyright management, anti-counterfeiting authentication, and transaction mechanisms for digital clothing assets to protect creators’ rights and interests;

- Formulating cross-platform interoperability standards for virtual clothing to enable cross-scenario circulation of digital garments;

- Building a fair value distribution system for creative contributions to ensure creators receive reasonable returns.

V. Challenges and Future: Weaving Visible and Invisible Value Networks

This full-link digital transformation also faces numerous profound challenges:

- High complexity of technology integration: The integration of legacy traditional systems with emerging digital platforms requires refined architecture design and technical adaptation to avoid data gaps or system conflicts.

- Risks of data privacy and security: Global data flows must strictly comply with regulatory requirements in different regions. How to protect user information and enterprises’ core data security has become an urgent problem for the industry to solve.

- Urgent need to rebuild organizational capabilities: The shift from traditional manufacturing thinking to digital ecosystem thinking requires enterprises to optimize talent structure and comprehensively upgrade corporate culture to adapt to the new business logic.

Nevertheless, enterprises that successfully overcome these challenges are reaping unprecedented competitive advantages. They are building not a single value chain but a value network connecting designers, manufacturers, retailers, and end-users—in this network, the exquisite craftsmanship of the physical world and the infinite possibilities of the digital world empower and enhance each other.

Conclusion: The New Grammar of the Fashion Industry

The global fashion industry is acquiring a brand-new “grammar”: in this system, physical fibers and data streams hold equal value, and physical experiences and digital expressions together form a complete cycle of brand meaning. This is by no means a mere application of technology but a fundamental restructuring of the industry’s underlying logic.

From high-end design studios in Milan to intelligent manufacturing centers in Shanghai, from trend retail spaces in New York to virtual fashion shows in the metaverse, this revolution is reshaping the operation mode of every link in the industry. Enterprises that take the lead in mastering this new grammar will not only define the future form of clothing products but also dominate the brand-new way the entire industry creates, delivers, and sustains value.

In this unfolding new industrial landscape, the ultimate winners will surely be industry integrators who can both master the exquisite craftsmanship of the physical world and leverage the innovative logic of the digital world to weave seamless consumption experiences for global consumers.